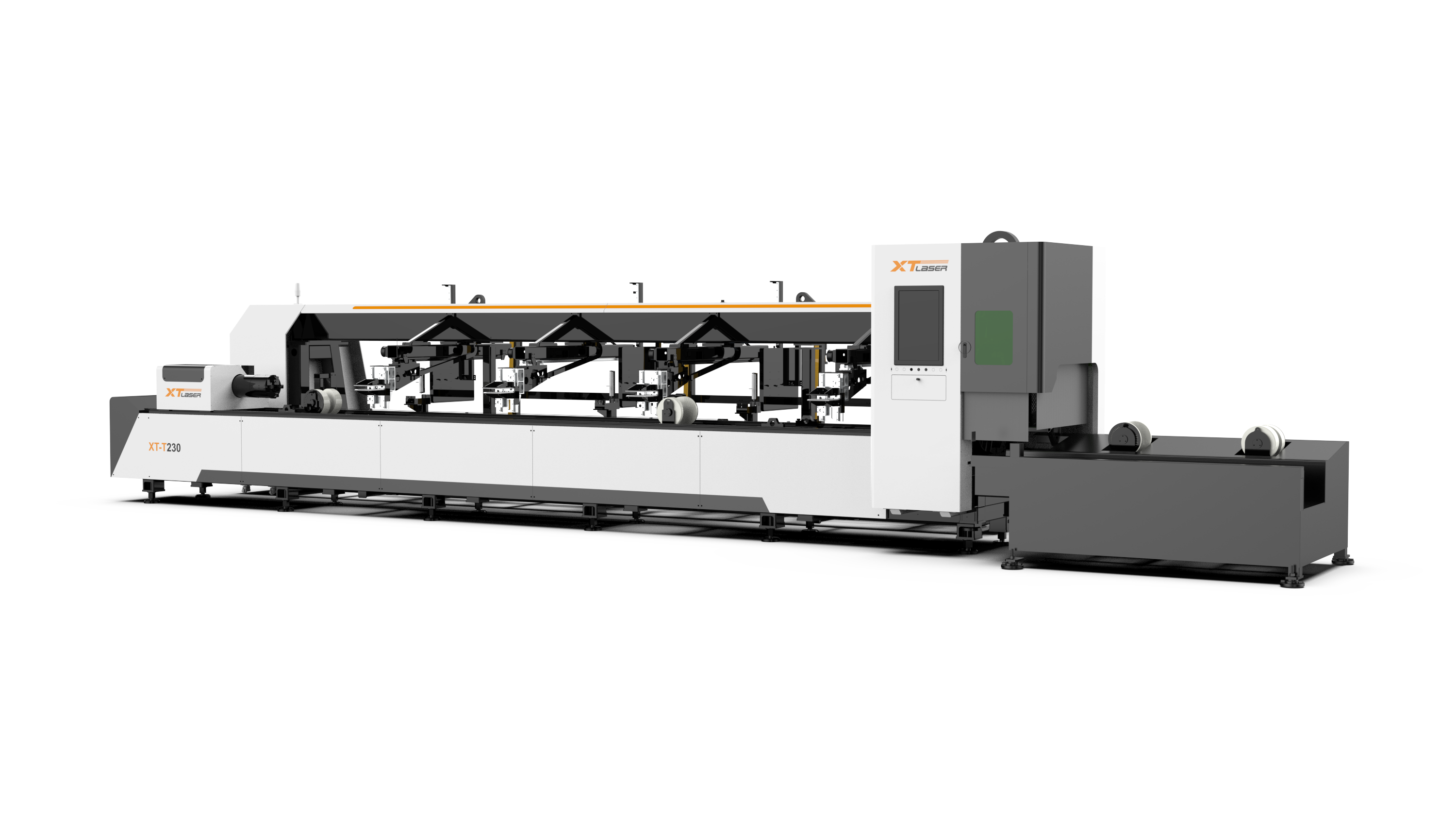

Metal fabrication has come a long way with the introduction of advanced technologies that have revolutionized the way metal products are created. One such technology that has gained immense popularity in recent years is fiber laser tube cutting machines. These cutting-edge machines are changing the landscape of metal fabrication, offering unmatched precision, speed, and versatility.

The current hotspots in the search trends for fiber laser tube cutting machines include precision cutting, automation, and versatility in materials. Let's take a closer look at these key areas and how fiber laser tube cutting machines are making a significant impact.

Precision Cutting: Accuracy like Never Before

One of the most significant advantages of fiber laser tube cutting machines is their unparalleled precision. These machines utilize high-powered laser beams that can be focused to a small spot size, allowing for precise and intricate cuts with minimal error. This level of accuracy is crucial in industries where tight tolerances are required, such as aerospace, automotive, and medical.

The precision cutting capability of fiber laser tube cutting machines enables the creation of complex shapes and intricate designs with ease. From straight cuts to bevel cuts, chamfer cuts, and even 3D cuts, these machines can achieve high-quality results consistently. This not only reduces material waste but also eliminates the need for costly rework, saving both time and resources.

Automation: Boosting Productivity to New Heights

Automation is another significant trend in metal fabrication, and fiber laser tube cutting machines are leading the way in this area. These machines can be easily integrated with automation systems, such as robotic loaders and unloaders, to streamline the production process and maximize productivity.

With automation, the material loading and unloading process becomes seamless and efficient, allowing for uninterrupted production and increased throughput. This not only reduces labor costs but also minimizes the chances of human error, ensuring consistent quality in the final product.

Versatility in Materials: Cutting a Wide Range of Metals

Fiber laser tube cutting machines are highly versatile and can cut a wide range of metals, including steel, stainless steel, aluminum, brass, and copper. This makes them suitable for various applications in different industries, from heavy machinery to delicate medical instruments.

The ability to cut different materials with ease makes fiber laser tube cutting machines highly adaptable to changing production requirements. This flexibility allows manufacturers to take on diverse projects and meet the ever-changing demands of their customers.

Conclusion

Fiber laser tube cutting machines are transforming the metal fabrication industry with their unmatched precision, speed, and versatility. These machines are enabling manufacturers to achieve higher levels of accuracy, boost productivity through automation, and cut a wide range of materials with ease. Keeping up with the current search hotspots, it's clear that fiber laser tube cutting machines are at the forefront of metal fabrication technology, providing innovative solutions for the modern manufacturing landscape.