Introduction:

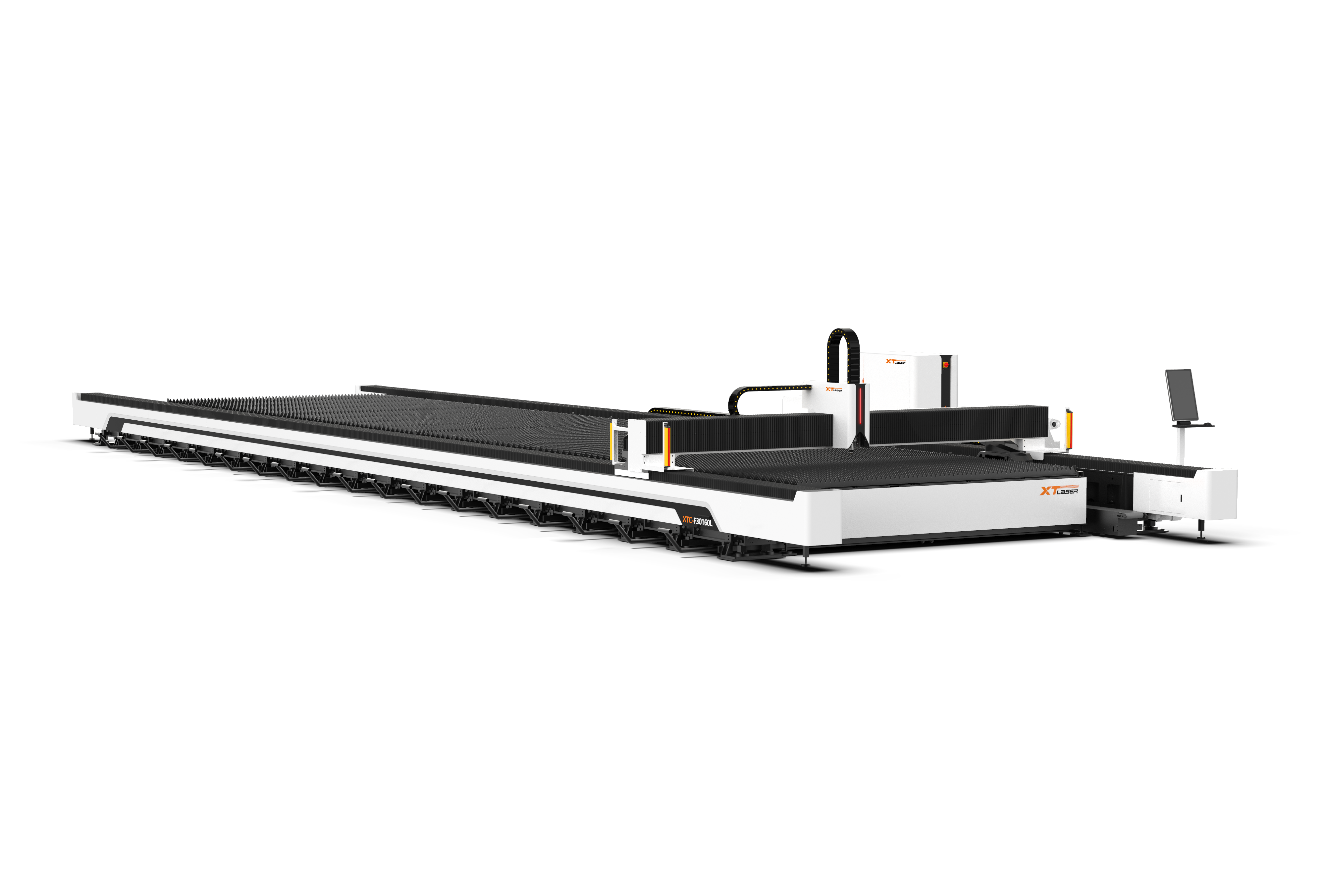

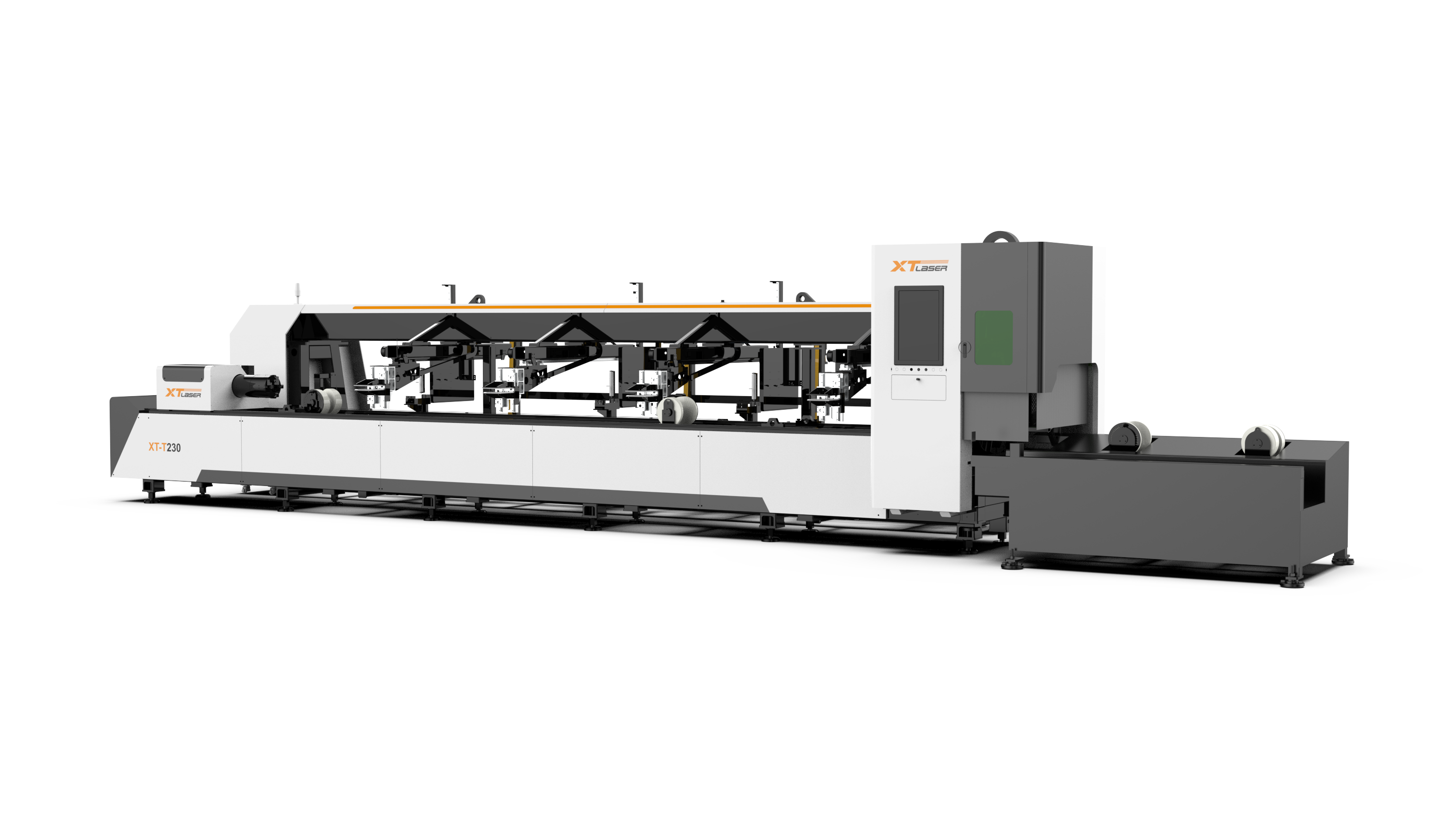

The manufacturing industry is constantly evolving, with businesses striving for precision and efficiency to stay ahead of the competition. One cutting-edge technology that is transforming the landscape is tube laser cutting machines. These machines are changing the game in manufacturing processes by offering unparalleled precision and efficiency in cutting tubes, pipes, and profiles. In this article, we will explore the advantages of tube laser cutting machines and how they can optimize your manufacturing operations.

The Power of Precision:

Tube laser cutting machines are renowned for their exceptional accuracy and precision. Equipped with advanced laser cutting technology, these machines can cut through various materials with utmost precision, resulting in clean, smooth, and burr-free cuts. This level of precision ensures high-quality end products and allows for complex and intricate designs, enabling customization according to your manufacturing requirements.

Unlocking Efficiency:

Tube laser cutting machines are designed to streamline manufacturing processes and boost productivity. With automated features, these machines can process tubes of different shapes, sizes, and thicknesses with minimal setup time, reducing downtime and increasing productivity. Moreover, they can handle multiple cutting tasks in a single operation, such as holes, slots, and mitre angles, saving time and labor costs and leading to faster turnaround times and higher production volumes.

Cost-effective and Sustainable Manufacturing:

Tube laser cutting machines offer significant cost savings in the long run. Their high precision and efficiency minimize material waste, as they optimize the cutting process to use the least amount of material required. This not only helps reduce material costs but also promotes sustainability by minimizing material waste. Additionally, the automated features of tube laser cutting machines reduce the need for manual labor, resulting in reduced labor costs and increased overall cost-effectiveness.

Versatility for Diverse Applications:

Tube laser cutting machines are versatile and suitable for a wide range of applications across different industries. Whether you need to cut tubes for frames, chassis, exhaust systems, handrails, or furniture components, tube laser cutting machines can handle the job with precision and efficiency. This versatility allows businesses to expand their manufacturing capabilities and cater to diverse customer needs, making them a valuable asset in the manufacturing industry.

Choosing the Right Tube Laser Cutting Machine:

Selecting the right tube laser cutting machine is crucial for integrating it into your manufacturing processes. Look for a reputable supplier that offers reliable machines with advanced features, excellent customer support, and comprehensive training for your operators. Consider the specific needs of your manufacturing operations, such as the size of tubes, material thickness, and desired production volumes, to ensure you choose the right tube laser cutting machine for your requirements.

Conclusion:

Tube laser cutting machines are revolutionizing the manufacturing industry with their precision, efficiency, and versatility. By investing in a high-quality tube laser cutting machine and integrating it into your manufacturing processes, you can optimize your production capabilities, reduce material waste, increase productivity, and stay ahead of the competition. Embrace the power of tube laser cutting machines and unlock new possibilities for your manufacturing operations.