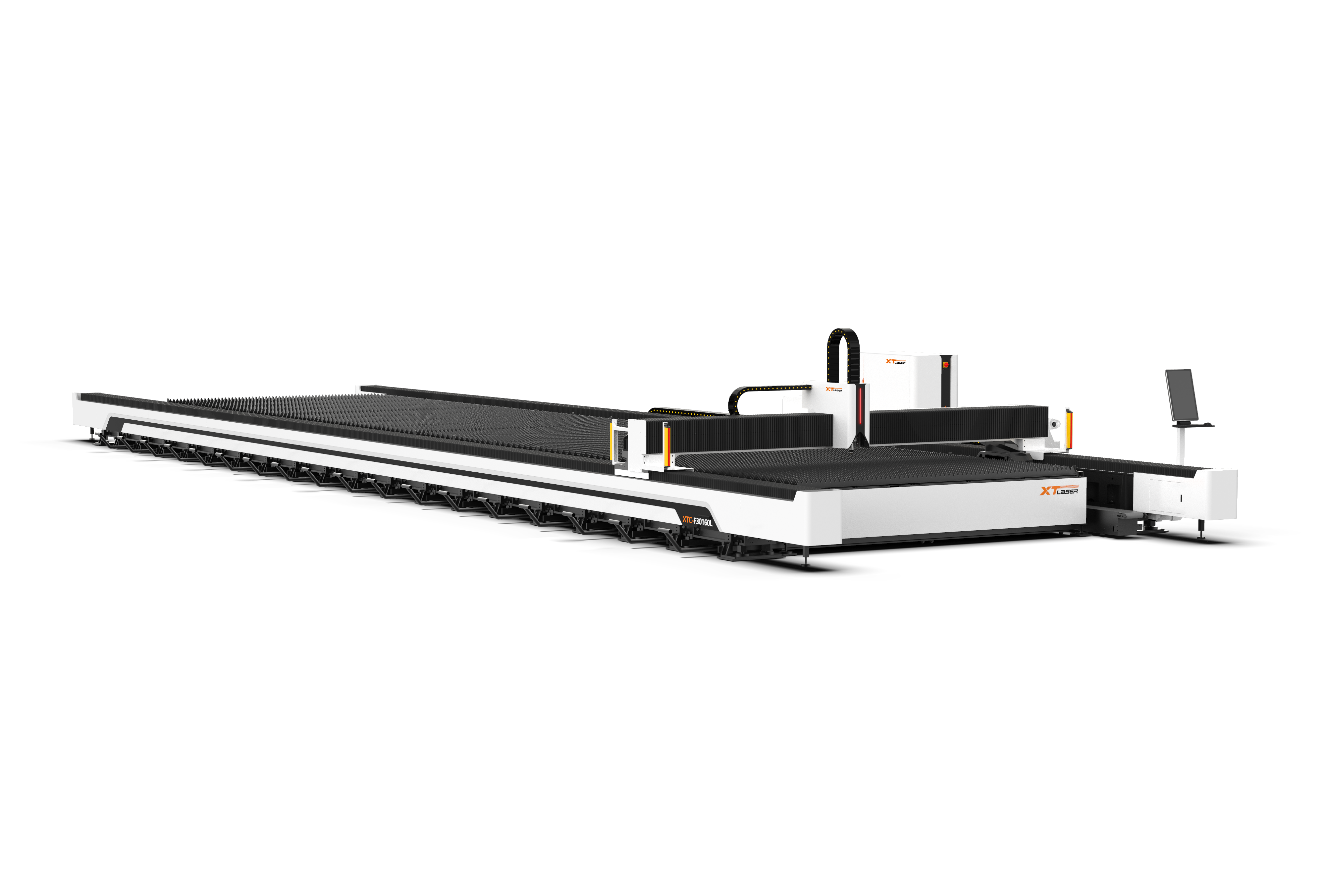

In today's industrial landscape, laser cutting machines have become a necessity for precision cutting of materials such as metal, plastic, and wood. Among the many options available, the 12KW fiber laser cutting machine stands out as one of the most powerful and efficient machines on the market. In this article, we'll explore the benefits of using a 12KW fiber laser cutting machine and how it can improve the efficiency and productivity of your industrial processes.

High Cutting Speed

The 12KW fiber laser cutting machine is designed to cut through thick and dense materials with precision and speed. With a power output of 12 kilowatts, this machine can cut through a wide range of materials quickly and accurately, saving you time and money in the long run. Compared to other laser cutting machines, the 12KW fiber laser cutting machine can cut through materials up to three times faster, making it an ideal choice for high-volume production.

In addition, the machine's high cutting speed allows for improved productivity and faster turnaround times. This means that you can complete more jobs in less time, increasing your output and revenue.

Improved Accuracy

In addition to high cutting speed, the 12KW fiber laser cutting machine also offers exceptional accuracy. With advanced features like real-time monitoring and automatic adjustments, this machine ensures that every cut is precise and consistent. The 12KW fiber laser cutting machine uses a fiber optic cable to deliver the laser beam, which allows for more precise and focused cuts compared to other cutting methods.

The machine's improved accuracy means that you can achieve a higher level of precision in your cuts, resulting in better quality finished products. This is particularly important for industries where accuracy is crucial, such as aerospace and medical equipment manufacturing.

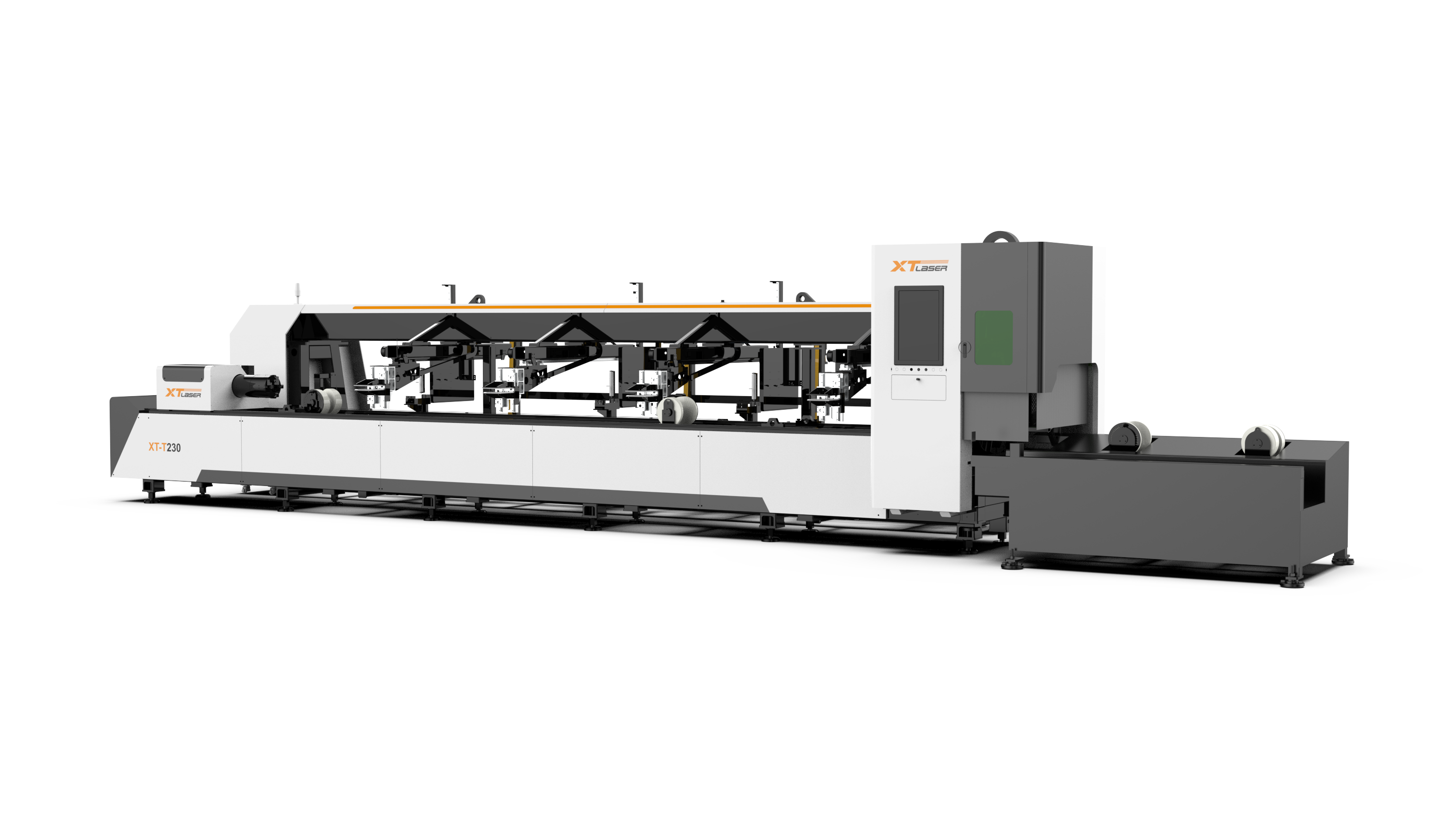

Versatile Cutting Capabilities

Another advantage of using a 12KW fiber laser cutting machine is its versatility. This machine can cut through a wide range of materials, including metals, plastics, and woods, making it ideal for a variety of industrial applications. Whether you're cutting complex shapes or simple designs, the 12KW fiber laser cutting machine can handle it all.

The machine's versatility also means that you can reduce the need for multiple cutting machines, saving you money and space in your workshop. This can be particularly beneficial for small businesses or those with limited space.

Energy Efficient

The 12KW fiber laser cutting machine is also designed to be energy-efficient, with a low power consumption rate compared to other laser cutting machines. This not only helps to reduce your energy costs but also makes it a more environmentally friendly option. The fiber optic cable used in this machine also has a longer lifespan, reducing the need for frequent replacements.

In addition, the machine's energy efficiency means that it generates less heat, reducing the risk of damage to materials and prolonging the life of the cutting head. This can save you money on replacement parts and repairs in the long run.

Easy Maintenance

Finally, the 12KW fiber laser cutting machine is designed to be easy to maintain. With fewer moving parts and a simple design, this machine requires less maintenance compared to other cutting methods. Routine maintenance tasks like cleaning and lubrication can be performed easily and quickly, reducing downtime and ensuring that your machine stays in top condition.

The machine's ease of maintenance means that you can spend more time cutting and less time on upkeep. This can improve your productivity and help you to complete jobs more efficiently.

In conclusion, the 12KW fiber laser cutting machine offers a range of benefits for industrial applications, including high cutting speed, improved accuracy, versatile cutting